Radioactive substance monitoring

With radiation imaging as its core technology. InsTech Netherlands solution for security inspection can effectively detect various kinds of hazardous items and contrabands including explosives, weapons, flammables, erosive items, candid cameras, wiretaps, radioactive substances and chemical and biological weapons.

With flexible configuration, high efficiency and user-friendly design, the security solutions can meet the needs in all industries. Based on high energy radiation imaging technology and by receiving the continuous x-ray spectrum generated by the accelerator (highest boundary energy ranges from 1MeV to 9MeV), InsTech Netherlands has successfully developed various series of inspection systems.

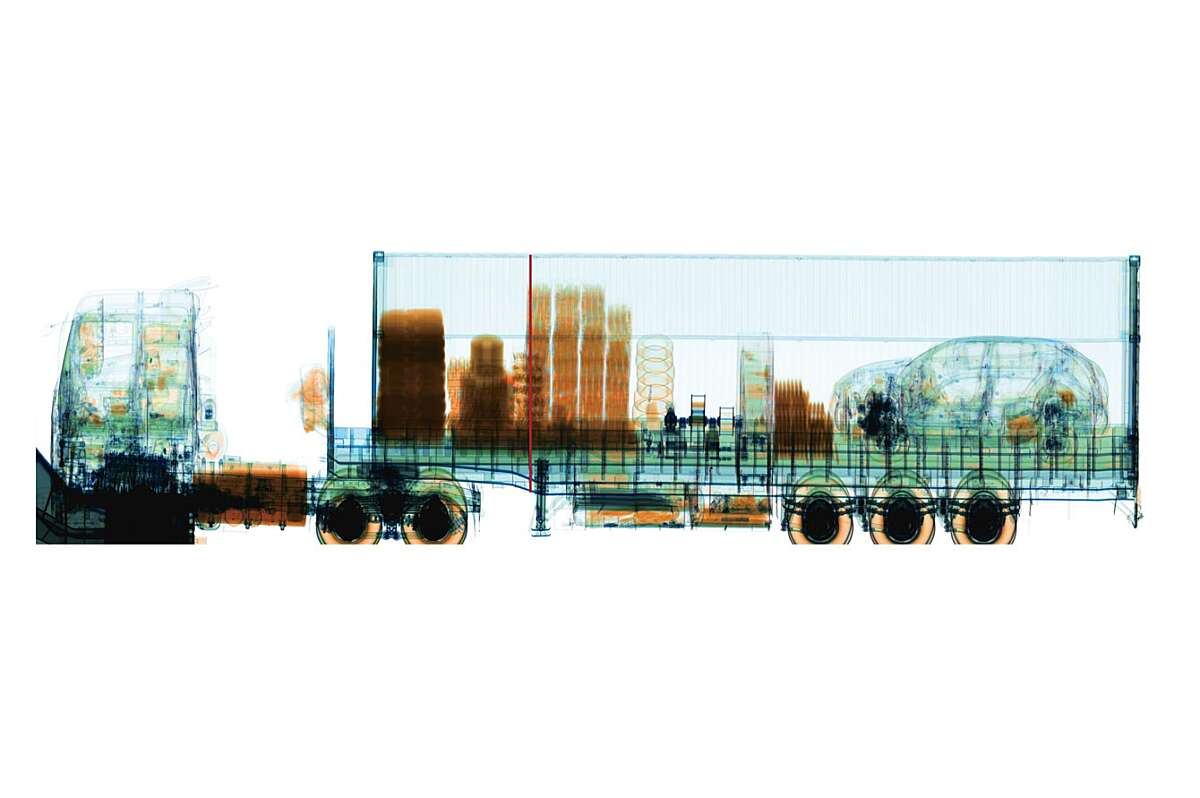

These include fixed, mobile and relocatable container/vehicle inspection systems, train inspection systems and fast-scan inspection systems, among which many are the very first of their kinds. The system is widely used in container inspection at customs, air cargo screening and train inspection.

Low energy x-ray imaging technology is mainly used in the baggage inspection system. InsTech Netherlands baggage inspection systems are designed with more advanced x-ray generators, high-resolution detectors, higher level image processing algorithms, ergonomic-principle-based user interface and diversified network programming for higher operation efficiency.

Dual-energy imaging technology was first used in the field of medical imaging and quickly spread out widely in bone mineral density measurement in the late 1970s. However, it remained a worldwide problem to make use of the high-energy and dual-energy x-ray generated by the accelerator and to apply it to inspect containers.

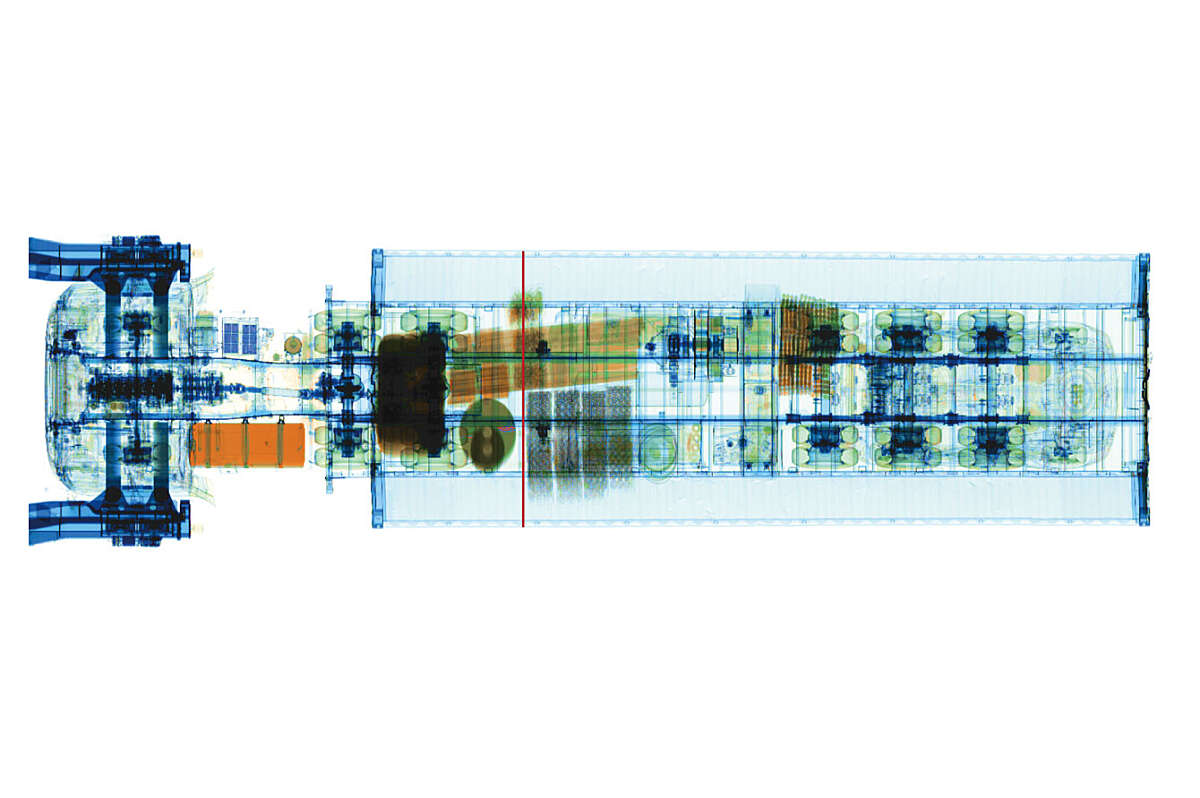

In 2001, InsTech Netherlands developed the world's first dual-energy x-ray container/vehicle inspection system. Through special processing, the system can inspect containers by two different types of x-ray with different energy generated by the same accelerator.

While producing two pieces of fluoroscopic image, the system can measure the equivalent atomic numbers of the goods in the containers so as to distinguish the materials including organic, inorganic and nuclear materials, which greatly boosted the capability of identifying the materials inspected.